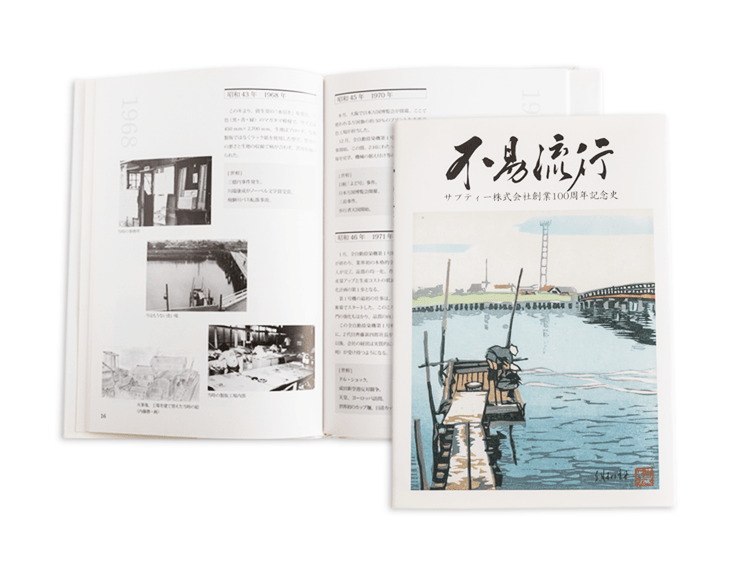

History

Over 100 years and still going strong

In our early days, SAPTI gained a reputation as a pioneer of signage in textile media, such as free-standing and hanging banners and armbands. Under our second president, we made our own contribution to Japanese society at the Osaka World Expo and the Tokyo Olympics. Under our third president, we embarked on full-scale mechanization and established a production system integrating all steps from printing through sewing, which still remains in operation today. We seek to win greater public trust as a company through our ongoing commitment to integrity in our craftsmanship, our service, and the way we do business.

| Year | Events at SAPTI | Events in the world at large | |

|

1912 |

|

|

| 1923 |

|

|

|

| Around 1943 |

Photo taken during the chaotic war years. The Burmese flag in the background was made to order by the firm. |

||

| 1945 |

|

|

|

|

1950 |

|

|

| 1953 |

|

||

| 1958 |

|

|

|

| 1959 |

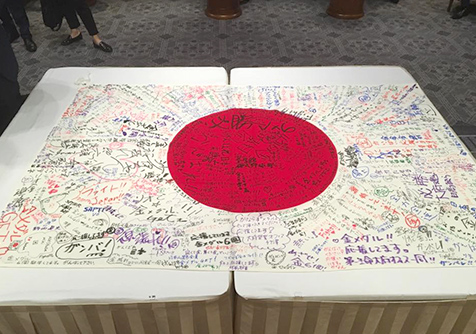

Producing the Japanese flag |

||

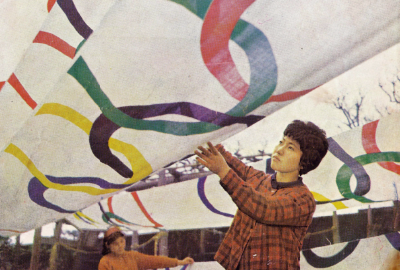

| 1964 |

|

|

|

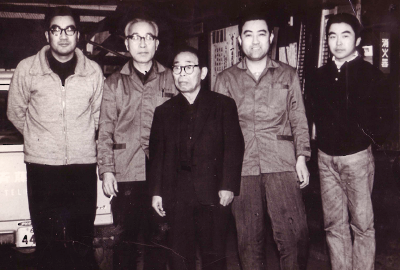

| 1967 |

Mr. Endo (center), the developer of pigment printing |

|

|

| 1970 |

|

|

|

| 1971 |

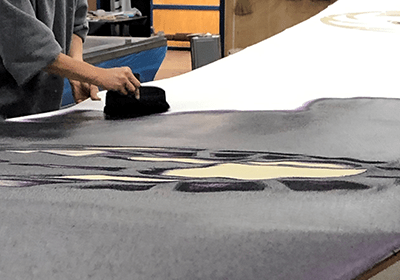

The company’s first fully automated textile printing machine |

||

| 1972 |

|

||

|

1976 |

|

|

| 1982 |

|

||

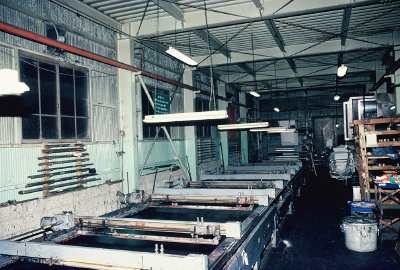

| 1984 |

Manual and mechanized operations were performed separately (Saito FP) |

||

| 1985 |

|

||

| 1988 |

|

||

| 1990 |

|

||

| 1991 |

|

||

| 1994 |

One of Japan’s largest fully automated textile printing machines |

||

| 1996 |

|

||

|

1998 |

|

|

| 2000 |

|

||

| 2003 |

|

||

| 2004 |

|

||

| 2006 |

|

||

| 2012 |

|

||

| 2013 |

|

||

| 2014 |

|

||

| 2014 |

|

||

| 2016 |

|

||

| 2017 |

|

||

| 2019 |

|

||

| 2020 |

|

||

| 2021 |

|

|

|

Fifth president |

2022 |

|

|

| 2024 |

|

||

| 2025 |

|

Washing dyed cloth in the Nakagawa River, ca. 1955. Woodblock print by Shintaro Narita.